Automated Yoke Style Closures

Simple, yet robust

Overview

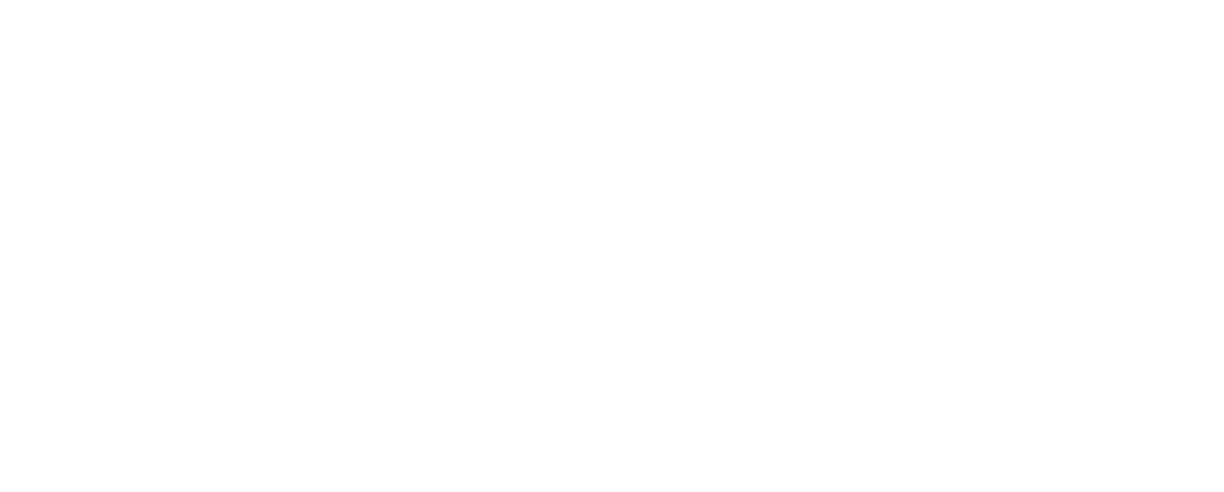

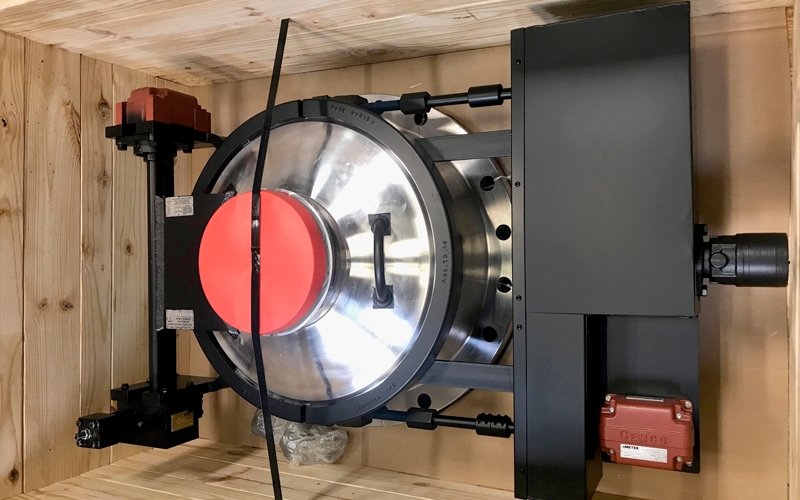

TUBE TURNS® offers Double-Bolt Yoke Style Closures / manways that are readily adaptable to a wide variety of operating aids ranging from single-lever chain and sprocket drives to completely automated designs, which can be operated by the touch of a button. This rapid-operating open/close automation can be driven by mechanical, electrical, hydraulic, or pneumatic power sources, to provide safe and convenient quick opening and closing for numerous applications beyond the Oil and Gas Industry.

Sypris’ automated quick opening closures / manways have been installed on super critical carbon dioxide (CO2) extraction vessels used for cleaning/purification of filtration media, specialized clothing, pharmaceutical applications and plant extraction processes. Sypris’ automated closures for these high pressure applications allow for reduced process times to increase the number of batches per day.

Sypris’ automated quick opening closures / manways can be installed on autoclaves & vacuum chambers for processing industrial composites, casting impregnation vessels, medical waste sterilizers & pressure test vessels. Sypris’ automated closures are supplied in carbon steel, stainless and duplex grades as required by customer.

Sypris’ automated quick opening closures / manways have been installed in numerous pressure chambers simulating high pressure undersea environments by US Navy and their contractors. The quick opening closures are customized with access ports and sight glass to meet each project’s specific needs.

Sypris’ automated quick opening closures / manways can be offered with hydraulic, pneumatic and electric drives with electronic controls as required. Automated quick opening closures are available in ASME CL 150 – 2500. The automated quick opening closures can be installed in horizontal or vertical orientation.

Sypris’ automated quick opening closures / manways are available in ASME Section VIII Division 1 or 2; they can be furnished with “U” stamp and U2A Partial Data Report form.

Our Automated Yoke Style Closures / manways have other advantages:

Safety

Automation provides a tight seal, which prevents leakage and exposure of the operators to any medium that may be potentially hazardous to their health.

Improved Employee Morale

With the environmental concerns in the industry today, Automated Closures enable the operator to be stationed away from the process, reducing their exposure to hazardous fluids. As a result, the operator's health risks are reduced significantly.

Economic Considerations

Depending on the size, the opening and closing cycle can take less than one minute. One operator can cycle the closure with the push of a button.

Maintenance

Since operation is simple, direct and positive, Automated Closures require little or no maintenance other than replacement of the O-ring and periodic inspection of yoke bolts and nuts for wear. The human element is virtually eliminated in that the automation mechanism of the closure performs all the work.

TUBE TURNS® Automated Closures have flexibility of design and can be developed and manufactured to meet your needs. Our Automated Closures are located in industries throughout the world. Applications for TUBE TURNS® Automated Closures include Pipeline Launchers and Receivers and operations with batch processes such as pulp and paper mills, food processing, chemical plants and petrochemical plants.

Styles Available

- Chain & Sprocket Automated Closures

- Electric Automated Closures

- Hydraulic Automated Closures

- Pneumatic Automated Closures

Products

Brochures & Manuals