Threaded Closures

Simple, yet robust

Overview

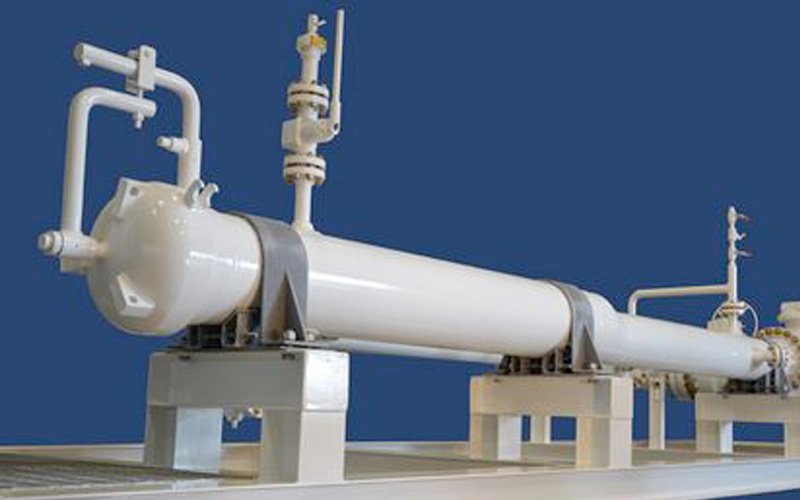

TUBE TURNS® manufactures Threaded closures in popular sizes ranging from 2" through 24" in ASME Pressure Class 150 through 900. Threaded closures in 26" through 42" are available in ASME Pressure Class 600. Threaded closures are available in horizontal and vertical orientations. Threaded closures offer safety with a simple design that consists of only a head, welding hub, pressure warning device, integrated tool to assist in opening and closing the larger size closures and heavy-duty hinging hardware with adjustable davit mechanisms on larger sizes. TUBE TURNS® Threaded Closures are manufactured utilizing the precision of CNC machining to provide accurate and consistent dimensions.

Safety

Threaded Closures meet ASME Section VIII, Division I requirements. Each Threaded Closure has a pressure-warning device to alert the operator of any internal pressure in the pipe or vessel before opening the head. Also, the O-ring gasket seal is broken before the Hub/Head ACME Threads are completely disengaged which allows pressure to bleed and provides additional warning to the operator of existing internal pressure.

Operational Assurance

To assure that the Threaded Closure will consistently open and close easily, TUBE TURNS® applies a Flouropolymer coating on the ACME head and hub threads that provides corrosion resistance and solid film lubrication. This coating, used in combination with appropriate lubricant on the threads, assures reliable closure operation. The Pressure Warning Device is manufactured from Stainless Steel to provide corrosion protection for this safety item.

Quality Assurance

TUBE TURNS® Quality Control System is in accordance with the American Society of Mechanical Engineers Boiler and Pressure Vessel Code, Section VIII, Division I, Appendix 10 and is audited by an Authorized Inspection Agency. ASME Code Stamping and Partial Data Reports are available at the time of order at a nominal extra cost.

Products

Brochures & Manuals