Ultra-High Pressure Closures

For Pressures Up to 15,000 psi

Overview

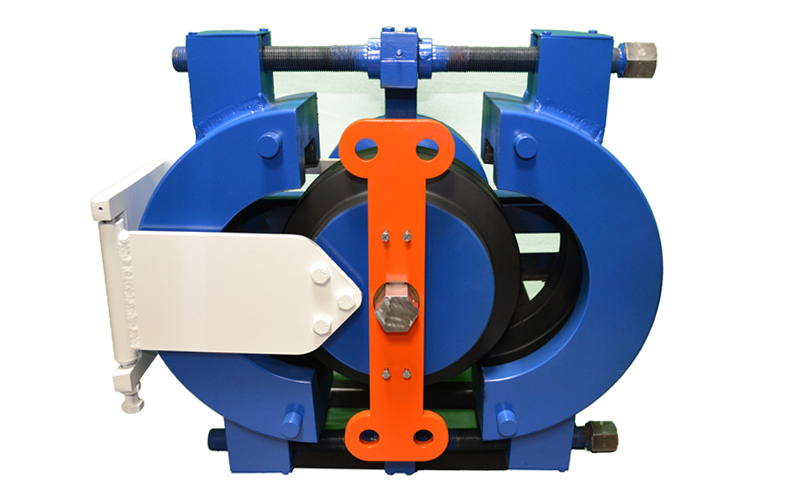

TUBE TURNS® UHP Ultra High Pressure closures provide a reliable, fast, safe and economical alternative for high-pressure vessels that require frequent access, such as high-pressure launchers and receivers, filters, or strainers.

Robust and Dependable

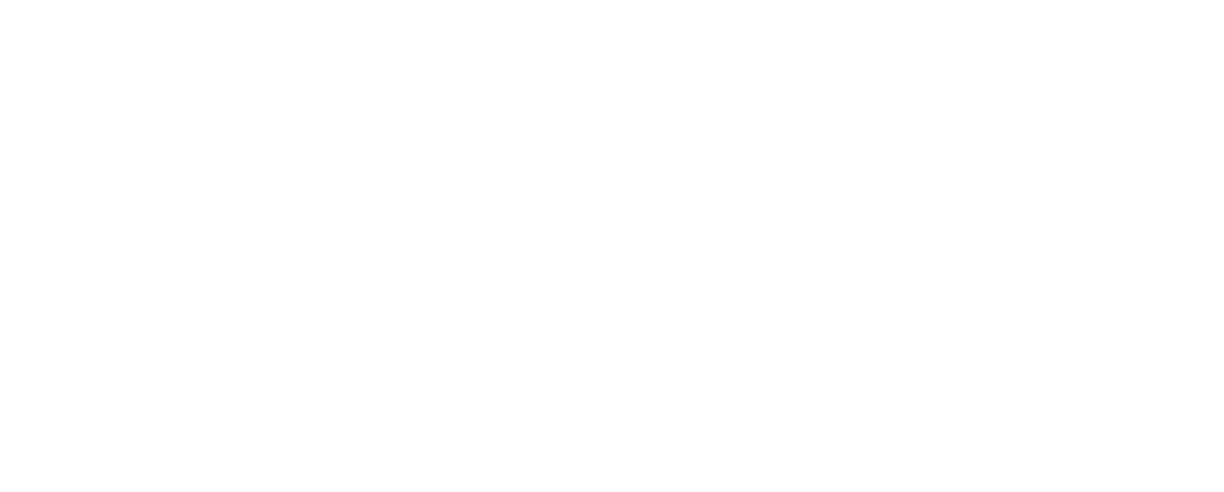

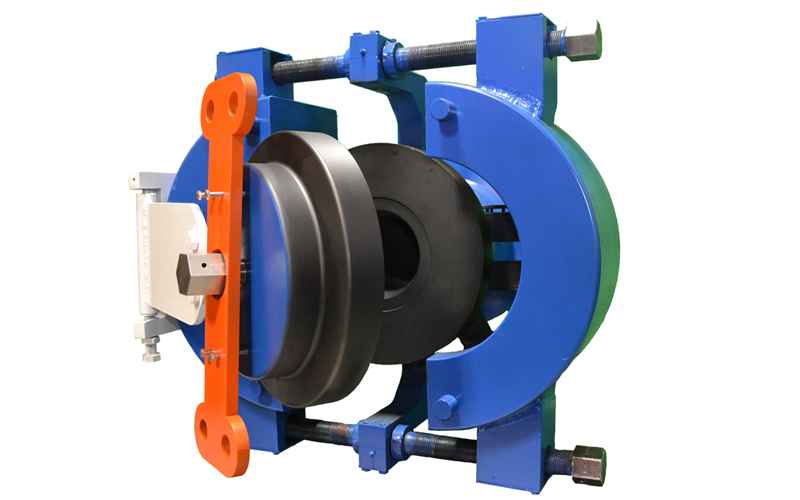

TUBE TURNS® UHP closures are the heavy-duty version of the TUBE TURNS® legacy line of clamp style (double bolt) closures that span more than 50 years of successful applications in a broad range of sizes and pressures. This Ultra High Pressure design utilizes a self-energized, metal-to-metal seal that allows pressure containment up to working pressures of 15,000 psi (1,034 bar). The clamping forces required to obtain this range of pressures is achieved by the use of two forged and machined heavy-duty clamps that are driven by dual heavy-duty, dual actuating drive screws. This combination ensures positive mating of the head and hub sections by encapsulating them in nearly 360° of clamping contact when the clamps are in the closed position.

Low Maintenance

TUBE TURNS® UHP closures include safety features to contain process fluid, protect operators and safeguard the environment. They feature a hinged cover with a pressure warning device and secondary mechanical interlock to prevent accidental opening under pressure. The fully redundant locking mechanism complies with ASME UG-35 (b). TUBE TURNS® UHP closures are faster and easier to operate than bolted connections. The low-maintenance design is also easier to service, with all wear parts readily accessible. All components except the main seal ring remain attached to the closure assembly, preventing loss or damage of loose parts.

Materials

We offer TUBE TURNS® UHP closures in a variety of materials, all of which are ASME/ASTM approved grades. Materials include low-alloy carbon steel, stainless steel, duplex stainless steel, carbon steel clad with Corrosion Resistant Alloy (CRA), and other corrosionresistant and/or high-strength materials. We carefully match material grades and thicknesses to assure compatibility of the closure welding hub with your connection point and welding processes. The major pressure boundary components of the closure are furnished with Mill Test Reports (MTRs).

Design & Quality

The TUBE TURNS® UHP closure design has been verified through proven stress calculations and the latest in finite element analysis (FEA) software, establishing a high level of confidence in the structural integrity of the closures. While adhering to ISO 9001:2008, we employ and follow strict quality control guidelines which are audited accordingly by an accredited third-party organization. All welding procedures have been written and developed in accordance with ASME Section IX and the accompanying NDE procedures per ASME Section V.

Products

Brochures & Manuals